"This has been my personal bench check for many, many years, the transfer bar needs a bit of room. The test is simple.

UNLOADED GUN, or, better yet, remove the cylinder.... and replace the base pin..

Cock the hammer. Pull the trigger and hold it in the "pulled position"..

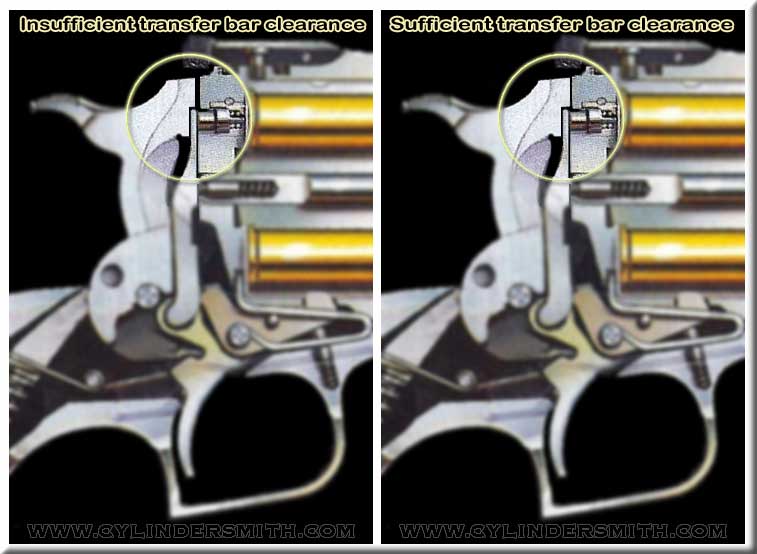

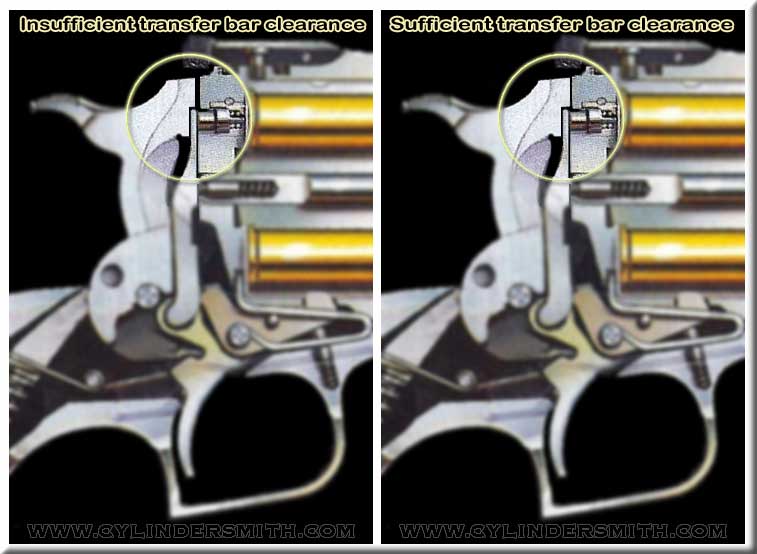

Watch the hammer very closely and slowly allow the trigger to return to the "at rest" position. Does the hammer move forward as the trigger moves forward, pulling the transfer bar back down away from the firing pin? If the hammer moved forward then it's pinching the transfer bar.

It's my opinion that the hammer nose should contact the cylinder frame when the New Model revolver is fired. A properly fitted transfer bar, via adjustment of the hammer's transfer bar notch and also "detail" polishing of the transfer bar, will still provide the 100% reliability we count on with our Rugers, but, will also increase the life of the transfer bar many times over."

With sufficient clearance the force of the hammer blow is shared evenly between the the frame and the transfer bar. The transfer bar is pushed forward enough to depress the firing pin without being battered between the hammer and the frame.